Introduction to 3D Printing Revolution

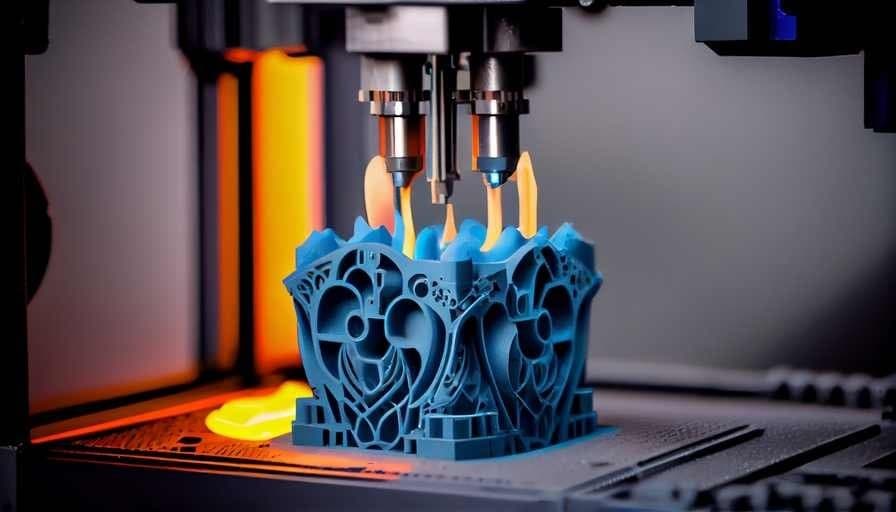

The manufacturing industry stands at the precipice of a technological revolution that promises to reshape how we conceive, design, and produce everything from simple prototypes to complex aerospace components. At the heart of this transformation lies 3D printing, or additive manufacturing – a technology that has evolved from a novel prototyping tool into a sophisticated production solution.

What began in the 1980s as a means to quickly visualize design concepts has now matured into a comprehensive manufacturing ecosystem that's disrupting established production paradigms across industries. Today's 3D printing technologies can work with an unprecedented range of materials, from traditional polymers and metals to cutting-edge composites and even biological materials.

The Evolution of Additive Manufacturing

The journey of 3D printing from concept to industrial reality represents one of the most significant technological advances in modern manufacturing. The technology has undergone remarkable evolution across multiple dimensions – precision, speed, material compatibility, and scale of application.

Early stereolithography systems could only work with photopolymer resins and produced parts with limited accuracy. Today's advanced systems can achieve layer resolutions as fine as 10 microns while working with high-performance materials including titanium alloys, carbon fiber composites, and specialized ceramics.

Key Benefits Transforming Industries

The adoption of 3D printing across industries is driven by a compelling set of benefits that address fundamental challenges in traditional manufacturing. These advantages extend beyond simple cost reduction to encompass strategic capabilities that can transform entire business models.

Perhaps the most immediately recognizable benefit is the ability to dramatically accelerate the prototyping process. Traditional prototyping methods often require weeks or months, while 3D printing compresses this timeline to hours or days. This speed advantage is amplified by the design freedom that additive manufacturing provides, enabling complex internal geometries and structures that would be impossible with traditional methods.

Industry Applications and Success Stories

The real-world impact of 3D printing is best understood through its diverse applications across industries. The aerospace industry has been among the earliest adopters, with companies like GE Aviation implementing 3D printed fuel nozzles that are 25% lighter and five times more durable than traditionally manufactured counterparts.

In healthcare, the technology enables patient-specific solutions that can be literally life-changing. Custom prosthetics, orthotics, and implants designed to match individual anatomy result in better fit, comfort, and functionality. The automotive industry leverages 3D printing for both rapid prototyping and production of low-volume specialty parts.

Current Challenges and Solutions

Despite its transformative potential, 3D printing technology faces several challenges that must be addressed for broader adoption. Production speed remains a limitation for high-volume manufacturing, though this is being addressed through improved hardware and multi-laser systems.

Quality consistency and part certification represent ongoing challenges, particularly in critical applications like aerospace and medical devices. Industry standards and certification processes are evolving to address these concerns, with organizations developing comprehensive standards for additive manufacturing.

Future Outlook and Emerging Trends

The future of 3D printing promises even more dramatic transformations as the technology continues to evolve. Artificial intelligence and machine learning are being integrated into printing systems to optimize parameters in real-time, predict failures, and ensure consistent quality.

Multi-material printing capabilities are expanding, enabling the creation of parts with varying material properties throughout their structure. This opens new possibilities for creating parts with embedded electronics, gradient properties, and optimized performance characteristics.

Conclusion and Next Steps

3D printing has undeniably transformed from a prototyping curiosity into a manufacturing force that's reshaping entire industries. Its ability to enable rapid iteration, mass customization, complex geometries, and sustainable production makes it an essential technology for modern manufacturers.

At S.A.M.S. Technical Services, we're committed to helping our clients navigate this technological transformation. Our expertise in 3D printing, combined with our comprehensive understanding of traditional manufacturing processes, enables us to provide integrated solutions that optimize both design and production.